Release time:2024-05-29

Our friends who struggle in the production line know itInjection moldingThere are some operating rules. We should know that safety is the primary productive force.

Injection molding machine is a complex machine with high temperature, high pressure and fast operation. The operator often neglects for a while, causing irreparable physical injury, and regrets for life. Every step of the operation of the injection molding machine is dangerous, especially when opening and locking the mold. In order to avoid danger, the operator must pay attention to the following details of safe operation during injection molding:

1. The injection molding factory shall keep the injection molding machine and its surrounding environment clean at all times. The space around the injection molding machine shall be kept as unobstructed as possible. After adding lubricating oil or pressure oil, the leaked oil shall be wiped clean as soon as possible. Before turning on the electric heating, please clean up the sundries (such as rubber particles) on the glue melting cylinder to avoid fire. If the machine is not overhauled or necessary, the heat insulation protective cover on the glue melting cylinder shall not be removed at will.

2. Before injection molding, check whether the mold locking can be terminated by pressing the emergency button or opening the safety door during operation.

3. When the shooting platform moves forward, it is not allowed to remove the deep glue leaked from the shooting nozzle by hand, so as to avoid pinching your hand between the shooting platform and the mold, causing physical injury. When cleaning the barrel, adjust the temperature of the nozzle to the appropriate high temperature, keep the nozzle unobstructed, and then use a lower injection pressure and speed to remove the residual rubber in the barrel. When cleaning, do not directly touch the newly injected rubber with your hands to avoid scalding.

4. Avoid placing heat sensitive and corrosive plastics in barrels for too long, and strictly follow the closing and cleaning methods provided by the plastic supplier. When replacing plastics, it is necessary to ensure that the new and old plastics will not produce chemical reaction after mixing (for example, if POM and PVC are mixed and heated successively, toxic gases will be produced); Otherwise, other plastics must be used to remove residues from the barrel.

5. Do not cancel the safety door or safety switch in order to improve the production speed. Before injection molding, check whether the mold is firmly installed on the moving template and head plate of the injection molding machine. Pay attention to whether the ground wire and other wiring of the injection molding machine are firmly connected.

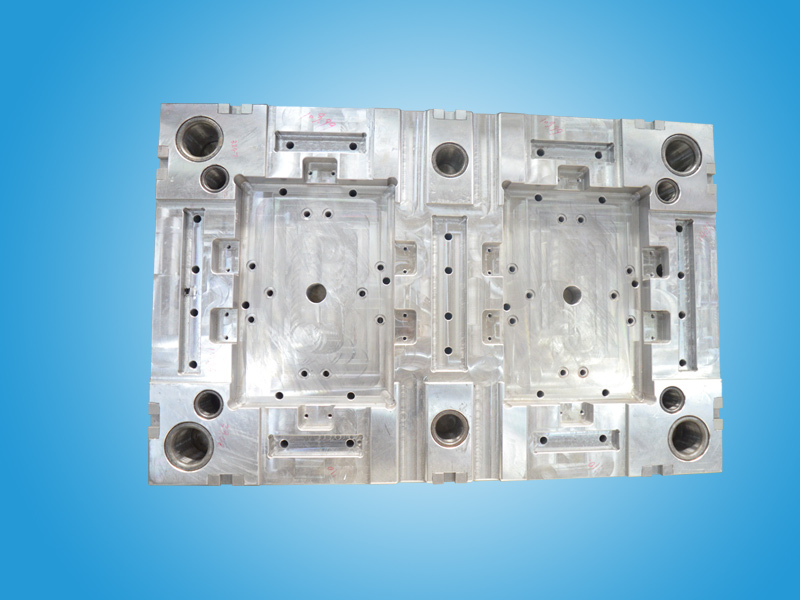

6. When installing the mold, the lifting ring must be completely screwed into the mold lifting hole before lifting. After the mold is installed, the length of the safety rod of the injection molding machine should be adjusted according to the size of the mold, so that when the safety door is opened, the machine safety stop (mechanical lock) can fall down to prevent the mold locking of the injection molding machine.

7. During the normal injection molding process, it is strictly forbidden for the operator to take out the injection molded parts from above or below the injection molding machine without opening the safety door. In case of mold maintenance or temporary shutdown, the oil pump motor of the injection molding machine should be shut down in time.

8. Injection molding can be operated by one person, and multiple people are not allowed. It is strictly forbidden for one person to operate the control panel while the other person adjusts the mold or does other operations at the same time.

Every operator of the injection molding plant should keep the above regulations in mind and ensure production safety while creating benefits.